|

|

| (27 intermediate revisions not shown) |

| Line 1: |

Line 1: |

| - | = Chapter 1 DE10-Advanced Development Kit = | + | = <span style="color:#000080;">Chpater1 Install Lithium Battery</span> = |

| - | The DE10-Advanced Development Kit provides users a combination of ARM software and FPGA hardware development platforms. It has a vast memory device and peripherals on the hardware. This kit also includes resourceful reference designs to help users to accomplish their design needs. The hardware offers in the DE10-Advanced has the maximum capacity with 660K Les in Arria 10 SoC FPGA and featuring various types of high-speed image interface such as: HDMI, Display Port, and 12G-SDI and a large capacity of DDR4 memory. The board’s high speed network interface, Gigabit Ethernet and SFP+10GbE, provides hardware resources for network communications related applications.

| + | |

| | | | |

| - | The HPS can be reboot with any of these three removable daughter cards: MicroSD Card, Nand Flash, and QSPI Flash. The FPGA on the main board can be connected to DDR4-SODIMM Socket in addition to the DDR4 memory module. The FPGA on the main board can also be connected to the Terasic QDR Memory Module as well. Beside the DDR4 memory module, you can also directly connect to the FPGA on the main board via the High Pin Count FMC expansion port to expand variety of functions.

| |

| | | | |

| - | The PCIe Gen3 x4 Connector interface comes with the Terasic PCA PCIe and PCIe Cable, which can be used to connect the Host PC to allow data between the FPGA and the Host PC. The USB Type-C interface on the motherboard allows the motherboard to obtain power for the host PC. The Host PC displays information and images through the high-speed transmission USB 3.0 or the Display Port. | + | The Self-Balancing Robot’s main power source is a lithium battery pack with three 12 V series 18650 batteries. For safety reasons, the lithium batterie are not included in the development kit. Users need to purchase three 18650 3.7V Lithium-Ion battery for the robot. The following linked products can be used as a reference for purchase: |

| - | ==1.1 Package Contents==

| + | |

| - | [[File:De10 advanced kit contents revc.jpg|700px]]

| + | |

| - | #DE10-Advanced SoC FPGA Development Kit

| + | |

| - | #MicroSD Card (Installed)

| + | |

| - | #Fan (Installed)

| + | |

| - | #Two Type A to Mini-B USB Cables

| + | |

| - | #12V DC Power Supply (Installed)

| + | |

| - | #AC Power Cord (USA)

| + | |

| - | #One 4GB DDR4 ECC SO-DIMM Module (Installed)

| + | |

| - | #Screws, Copper Stands, and Silicon Footstands

| + | |

| - | ==1.2 DE10-Advanced System CD==

| + | |

| - | The DE10-Advanced System CD contains all the documents and supporting materials associated with DE10-Advanced, including the user manual, system builder, reference designs and device datasheets. Users can download this system CD from the link: http://DE10-Advanced.terasic.com/cd.

| + | |

| | | | |

| - | ==1.3 Getting Help==

| |

| - | *Here are the addresses where you can get help if you encounter any problems:

| |

| - | *:

| |

| - | **Terasic Technologies

| |

| - | *:

| |

| - | **9F., No.176, Sec.2, Gongdao 5th Rd, East Dist, Hsinchu City, 30070. Taiwan

| |

| - | *:

| |

| - | **Email: support@terasic.com

| |

| - | *:

| |

| - | **Tel.: +886-3-575-0880

| |

| - | *:

| |

| - | **Website: DE10-Advanced.terasic.com

| |

| | | | |

| - | = Chapter 2 Introduction of the DE10-Advanced Board=

| + | [https://www.digikey.com/product-detail/en/sparkfun-electronics/PRT-12895/1568-1488-ND/5271298 https://www.digikey.com/product-detail/en/sparkfun-electronics/PRT-12895/1568-1488-ND/5271298] |

| - | This chapter provides an introduction to the features and design characteristics of the board.

| + | |

| - | ==2.1 Layout and Components==

| + | |

| - | Figure 2-1 and Figure 2-2 shows a photograph of the board. It depicts the layout of the board and indicates the location of the connectors and key components.

| + | |

| | | | |

| - | [[File:De10 advanced revc layout top.jpg|720px]]

| |

| | | | |

| - | :::::::Figure 2-1 DE10-Advanced development board (top view) | + | <span style="color:#0000ff;">'''Note that only the 18650 batteries with a length of 65 mm can be installed in the battery case on the robot. Do not purchase batteries longer than this length, otherwise they will not fit into the battery case.'''</span> |

| | | | |

| - | ::::[[File:De10 advanced revc layout bot.jpg|520px]]

| |

| | | | |

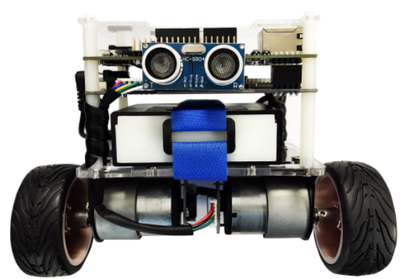

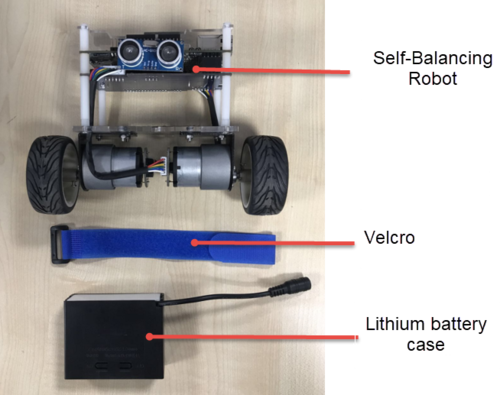

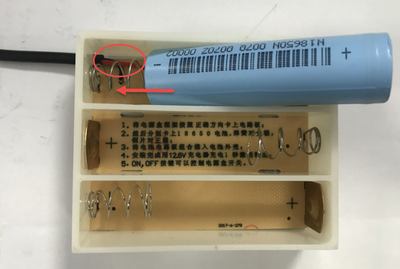

| - | ::::::Figure 2-2 DE10-Advanced development board (bottom view) | + | <div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_1.png|400px]]</div> |

| | | | |

| - | The DE10-Advanced board has many features that allow users to implement a wide range of designed circuits, from simple circuits to various multimedia projects.

| |

| | | | |

| - | The following hardwares are provided on the board:

| + | Next, please open the balance car's kit packaging, remove the robot. Remove the lithium battery case from the Self-Balancing Robot, install the battery and reload it into the car. |

| | | | |

| - | *'''FPGA Device'''

| + | Detailed steps are as follows: |

| - | **Intel ® Arria10® SoC 10AS066K3F40E2SG device (660K LEs)

| + | == 1-1 Remove the lithium battery case == |

| - | **USB-Blaster II onboard for programming; JTAG Mode

| + | |

| - | **Serial configuration device – EPCQL1024

| + | |

| - | **One DDR4 SO-DIMM Socket, support ECC

| + | |

| - | **On-board 1GB DDR4-2400, 32-bit data width

| + | |

| - | **USB Type-C Interface

| + | |

| - | **Power Delivery

| + | |

| - | **DisplayPort TX/RX with 4 lanes

| + | |

| - | **USB 3.0/2.0

| + | |

| - | **HDMI TX/RX 2.0 for 4K2K@60- FPGA Transceiver

| + | |

| - | **PCIe Cabling Socket at Gen3 x4

| + | |

| - | **SFP+ Socket x4, 40Gbps

| + | |

| - | **SATA 3.0 Host and SATA Device x2 (SATA Connector x4)

| + | |

| - | **One Gigabit Ethernet Port

| + | |

| - | **SMA Clock-In and Clock-Out

| + | |

| - | **High Pin Count FMC Connector. Support VADJ 1.2V/1.5V/1.8V.

| + | |

| - | **Accelerometer, Gyroscope and Magnetometer

| + | |

| - | **Temperature Sensor

| + | |

| - | **Fan Control

| + | |

| - | **LED x2, KEY x2, Switch x2, 7-Segment x2

| + | |

| | | | |

| - | *'''HPS (Hard Processor System)'''

| |

| - | **1.5GHz Dual-core ARM Cortex-A9 processor

| |

| - | **Boost Flash Slot:

| |

| - | **1024 Mb QSPI Flash

| |

| - | **Nand Flash

| |

| - | **MicroSD Socket

| |

| - | **On-board 1GB DDR4-2400, 32-bit data width

| |

| - | **1 Gigabit Ethernet PHY with RJ45 connector

| |

| - | **USB OTG Port, USB mini-AB connector

| |

| - | **UART to USB, USB Mini-B connector

| |

| - | **RTC

| |

| - | **One user button and one user LED

| |

| - | **Warm reset button and cold reset button

| |

| | | | |

| - | ==2.2 Block Diagram of the DE10-Advanced Board==

| + | # Remove the package box from the robot, |

| - | Figure 2-3 is the block diagram of the board. All the connections are established through the Arria 10 SoC FPGA device to provide maximum flexibility for users.

| + | #: |

| - | Users can configure the FPGA to implement any system design.

| + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_2.png|400px]]</div> |

| | + | #: |

| | + | #: |

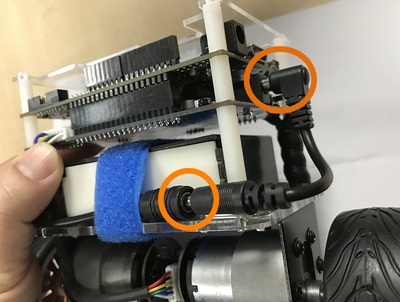

| | + | # Release the Velcro, take the strap off of the lithium battery case. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_3.png|400px]]</div> |

| | + | #: |

| | + | # The Battery case parts distribution is shown below after removing the battery case. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_4.png|500px]]</div> |

| | + | #: |

| | | | |

| - | [[File:De10 advanced revc block diagram.jpg|500px]]

| + | == 1-2 Install the batteries into the lithium battery case == |

| | | | |

| - | ::::Figure 2-3 Block diagram of DE10-Advanced

| |

| | | | |

| | + | # The purpose of the lithium battery case is to prevent the lithium battery from exceed the safety value while charging; at the same time, it also protects the battery from damage in case the voltage is too low. When first opening the balance car package, the lithium batteries are not in the battery case. The users need to install the three 18650 lithium battery into the battery case. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | # The battery compartment has a slot design. The black cover will secure the white battery holder. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_5.png|300px]]</div> |

| | + | #: |

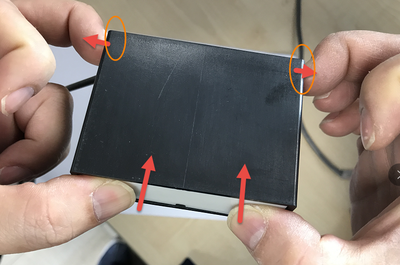

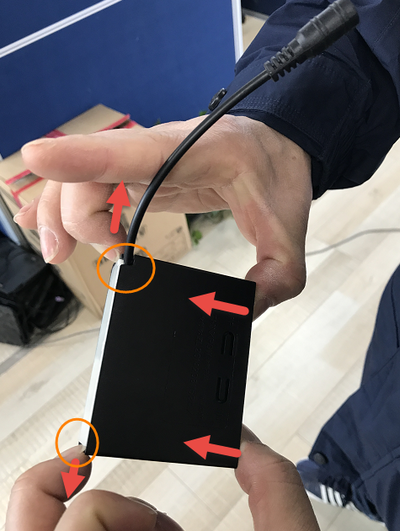

| | + | # We suggest users open the battery case with both hands. First, locate the little slots on the left and right sides of the battery case. Second, slightly push the cover outward to take it out of #:the battery compartment. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_6.png|400px]]</div> |

| | + | # Use the left and right middle fingers to slightly push the center tabs out. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_7.png|400px]]</div> |

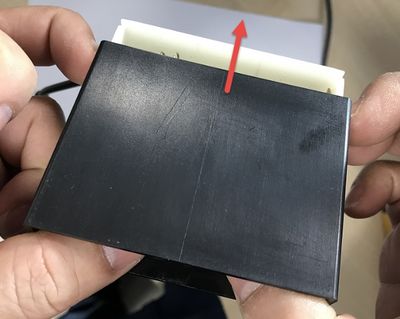

| | + | # Next, use both thumbs to push the white battery compartment forward, and then the battery case should be opened. The battery cover and compartment can be connected tightly; therefore, users might need to use more strength. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_8.png|400px]]</div> |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_9.png|400px]]</div> |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_10.jpg|400px]]</div> |

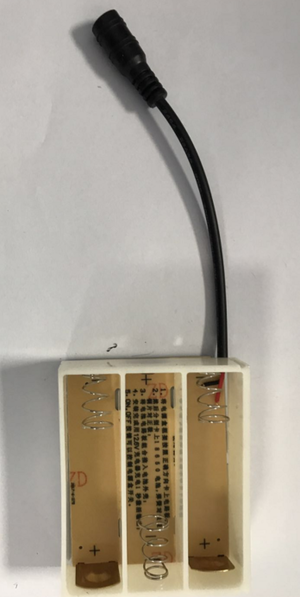

| | + | # Remove the battery compartment. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;margin-left:0.635cm;margin-right:0cm;">[[Image: BAL_01_Battery_Installation_Guide_pic_11.png|300px]]</div> |

| | + | #: |

| | + | #:<div style="margin-left:0.635cm;margin-right:0cm;">The battery case contains two parts: the battery cover and a PCB board. If it becomes lose, you can follow the picture below to put it back together.</div> |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_12.png|400px]]</div> |

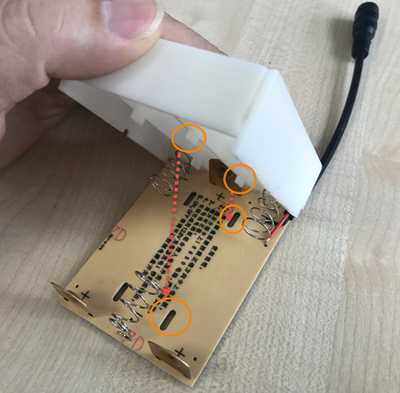

| | + | # Prepare three 18650 lithium batteries and follow the instructions to insert the batteries positive and negative sides accordingly. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_13.png|400px]]</div> |

| | + | #: |

| | + | #:<div style="margin-left:0.635cm;margin-right:0cm;">The positive and negative battery installation and distribution are as follows:</div> |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_14.png|300px]]</div> |

| | + | #: |

| | + | #:<div style="margin-left:0.635cm;margin-right:0cm;">'''Note,''' in the slot with the power cord the battery will not go in as easily due to the wire connection, be sure to push harder on the battery to ensure that is goes into the slot. </div> |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_15.png|400px]]</div> |

| | + | # After the batteries are inserted, please double check the batteries positive and negative polarity on each battery are positioned correctly. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;margin-left:0.635cm;margin-right:0cm;">[[Image: BAL_01_Battery_Installation_Guide_pic_16.png|200px]]</div> |

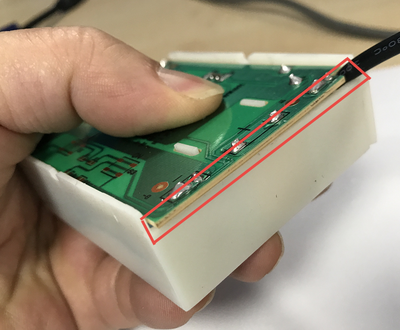

| | + | # Make sure the back of the PCB has good bonding with the battery cover and can be closed smoothly. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_17.png|400px]]</div> |

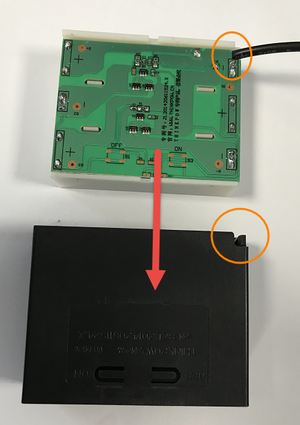

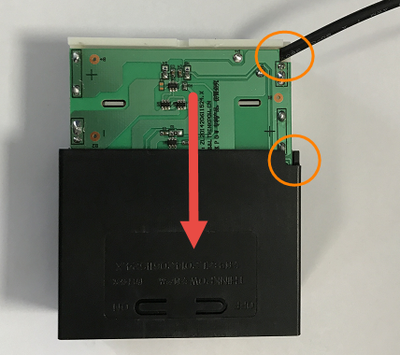

| | + | # When replacing the battery cover, please make sure that the power cord has a notched position corresponding to the case. This allows the case to be reassembled without damaging the power cord or the case. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_18.png|300px]]</div> |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_19.png|400px]]</div> |

| | + | # <span style="color:#ff0000;">'''Caution!'''</span><span style="color:#ff0000;"> Despite the charging status, batteries need to be connected to a charger due to the circuit design of the battery to activate the output voltage circuit. Otherwise, there will be no power output. The battery box needs to stay connected to the charger for at least 1 second. If there is no battery replacement, then users do not need to repeat this step.</span> |

| | + | #: |

| | + | #: |

| | + | #: |

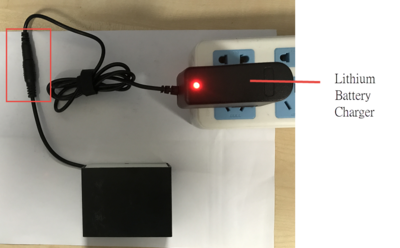

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_20.png|400px]]</div> |

| | + | #: |

| | | | |

| - | Detailed information about Figure 2-3 are listed below.

| + | == 1-3 Insert the lithium battery case back into the robot == |

| | | | |

| - | *Arria 10 SoC 10AS066K3F40E2SG/10AS057K3F40E2SG FPGA

| |

| - | **Dual-core ARM Cortex-A9 (HPS)

| |

| - | **660K programmable logic elements

| |

| - | **42,660 Kbits embedded memory

| |

| - | **Hard memory controllers x5

| |

| - | **Transceivers x48(17.4 Gbps)

| |

| - | **18-bit x 19-bit multipliers x3,356

| |

| - | **Accelerometer & Gyroscope Device MPU9250

| |

| | | | |

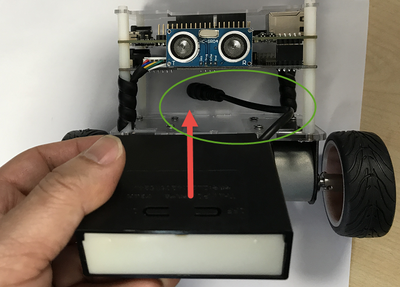

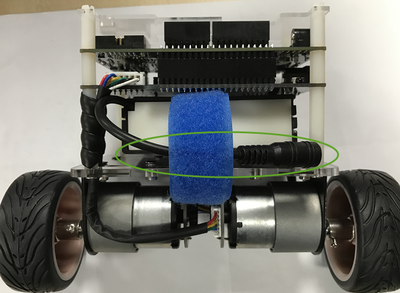

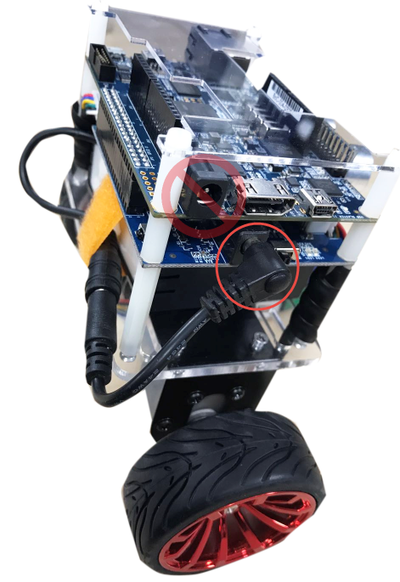

| - | *Configuration

| + | # Once the battery case has been reassembled, follow the picture illustration below to place the battery case back into the robot. Please make sure to place the battery case in empty space in the middle of the robot, as indicated in the picture. This action will ensure that the wires are neatly placed in the proper location. |

| - | **EPCQ1024L Serial Configuration Device

| + | #: |

| - | **Onboard USB-Blaster II (Mini-B USB connector)

| + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;margin-left:0.635cm;margin-right:0cm;">[[Image: BAL_01_Battery_Installation_Guide_pic_21.png|400px]]</div> |

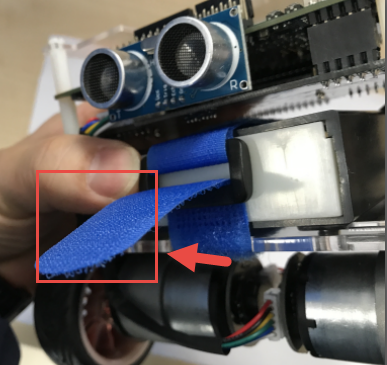

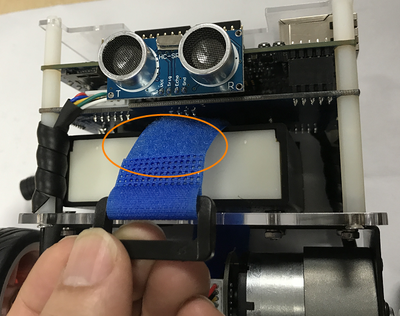

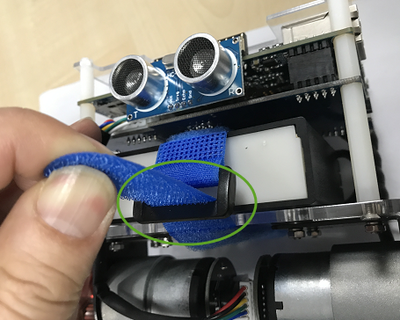

| | + | # Insert the blue Velcro strap (with the plush side up) between the battery and the robot. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_22.png|400px]]</div> |

| | + | # Pay attention to the power cord tied to the cable tie in the back of the car. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_23.png|400px]]</div> |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_24.png|400px]]</div> |

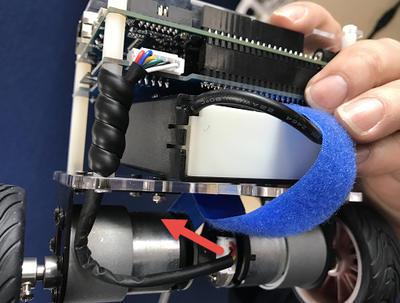

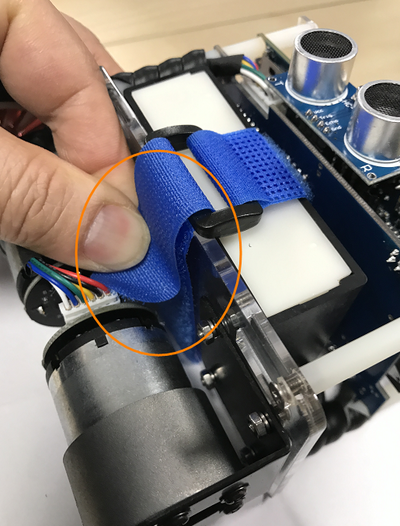

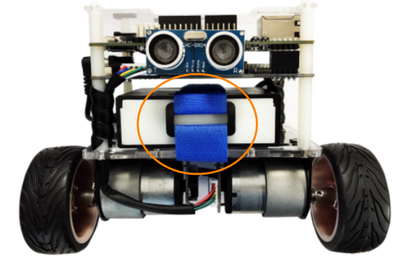

| | + | # To tighten and secure the lithium battery box and the body, tie Velcro from the bottom of the body back to the front body through the black ring. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_25.png|400px]]</div> |

| | + | # Tie the Velcro down to secure the battery case. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_26.png|400px]]</div> |

| | + | # Users can adjust the black ring to their desire spot. It’s the best to tie it securely to the body. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_27.png|400px]]</div> |

| | + | # Use the DC power cable (can be found in the Package Box) to connect the lithium battery case to robot’s power input. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_28.png|400px]]</div> |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_29.png|400px]]</div> |

| | + | #: |

| | + | #:Please note that do not plug the DC power cable into the DE10-Nano 5V power jack |

| | + | #: |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_30.png|400px]]</div> |

| | + | #: |

| | + | #: |

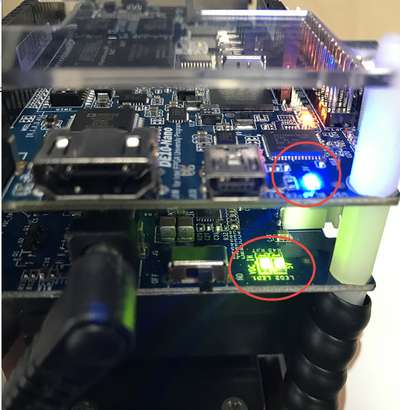

| | + | # To test whether the battery has normal power supply or not, turn the system power switch to the right. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_31.png|400px]]</div> |

| | + | # If the power is normal, users will see the green LED lit up; the DE10-Nano blue power light will also be lit up. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_32.png|400px]]</div> |

| | + | # If the LEDs fail to be lit up: |

| | + | ## Please check if the DC power cable is connected properly. |

| | + | ## Every time the batteries are installed, please make sure the battery charger is attached to the battery box for at least one second to activate the battery power output. |

| | + | ## If there is still no power output after completing the two actions above, remove the battery case, and check the batteries to see if the positive and negative polarity of the batteries are installed correctly. |

| | + | #: |

| | + | #: |

| | + | #: |

| | + | #:<div style="margin-left:0.635cm;margin-right:0cm;"></div> |

| | + | #: |

| | + | #:<div style="margin-left:0.635cm;margin-right:0cm;">If you are still having problems, please contact support@terasic.com for further assistance.</div> |

| | | | |

| - | *Memory Device

| + | = <span style="color:#000080;">Chpater2 Install Battery of Remote Control</span> = |

| - | **On-board 1GB DDR4-2400, 32-bit data width

| + | |

| - | **Two DDR4 SO-DIMM SDRAM socket

| + | |

| - | **Micro SD card socket

| + | |

| | | | |

| - | *Communication

| |

| - | **USB OTG (Mini-AB USB connector)

| |

| - | **UART-to-USB (Mini-B USB Connector)

| |

| - | **Giga Ethernet x2

| |

| - | **PCIe Gen3 x4 Cabling Socket

| |

| | | | |

| - | *Expansion Ports

| |

| - | **FMC connector

| |

| - | ***one HPC(high-pin count) FMC connector with xcvr

| |

| - | ***Adjustable VADJ:1.2V/1.5V/1.8V

| |

| | | | |

| - | *Multimedia Interface

| |

| - | ** HDMI TX and RX ports

| |

| | | | |

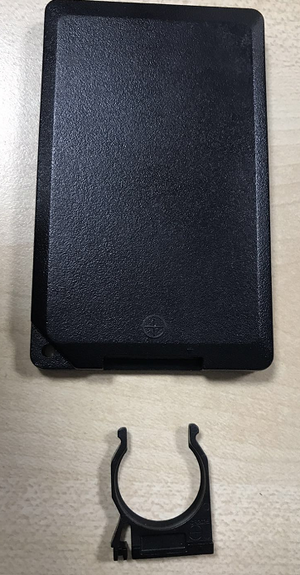

| - | *Clock

| + | For safety reasons, the battery of the infrared remote control is not installed in the package. If the user needs to use the remote control, user needs to buy a CR2025 Lithium Button Cell (available at most electronic and drug stores). |

| - | **Two SMA connectors for SMA Clock-In and Clock-Out

| + | |

| - | **On-board PLLs

| + | |

| | | | |

| - | *General user input/output | + | The specifications of the battery are as follows: * Type :CR2025 Lithium Button Cell |

| - | **Buttons x3 (FPGA x2, HPS x1) | + | * Voltag : 3V |

| - | **Switches x2 on FPGA | + | * Diameter : 20mm |

| - | **LEDs x3 (FPGA x2, HPS x1) | + | * Height: 25mm |

| - | **7-segment displays x2

| + | |

| | | | |

| - | *System Monitor and Control

| |

| - | **Temperature Sensor on FPGA

| |

| - | **12V Power Monitor

| |

| - | **Power Controller

| |

| - | **I2C Fan Control

| |

| | | | |

| - | *Power

| |

| - | **12V DC input

| |

| | | | |

| - | = 3 Chapter 3 Board Setting and Status component =

| + | [[Image: BAL_01_Battery_Installation_Guide_pic_33.png|100px]] |

| - | This chapter describes all the setting devices on DE10-Advanced board and their functions, such as Switches and Headers. We also will describe the function of some status LEDs. The JTAG interface will be described at the end of this chapter.

| + | |

| - | ==3.1 Board Setting Switches==

| + | |

| | | | |

| - | *'''Mode Select Switches'''

| + | Installation steps: |

| - | Mode Select Switch(SW5) is used to set the DE10-Advanced FPGA MSEL pin value.These MSEL pins determined the Configuration Mode of the FPGA.Table 3-1 list the MSEL setting for configuration scheme of FPGA,when MSEL is set to AS mode(Factory default setting),FPGA will be booted from EPCQ device(See Figure 3-1).When MSEL is set to FPP mode(See Figure 3-2),FPGA can be configured by HPS Fabric(From Micro SD Card).

| + | # Turn the infrared remote upside down and slide the battery tray out, as illustrated below. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_34.png|400px]]</div> |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_35.png|300px]]</div> |

| | + | # With the positive side facing up toward you, put in the CR2025 battery. |

| | + | #: |

| | + | #:<div style="text-align:left;">[[Image: BAL_01_Battery_Installation_Guide_pic_36.png|300px]]</div> |

| | + | # Slide the battery tray back into the infrared remote until it clicks. |

| | + | #: |

| | + | #:<div style="text-align:center;"></div> |

| | | | |

| - | :::'''Table 3-1 MSEL setting for configuration scheme of FPGA'''

| + | = <span style="color:#000080;">Chpater3 Additional Information</span> = |

| - | :{| class="wikitable"

| + | |

| - | |-

| + | |

| - | !Configuration Scheme !!SW5 MSEL[2..0] Setting !!Description

| + | |

| - | |-

| + | |

| - | |AS Mode (Factory Default) ||010|| FPGA boot from EPCQ

| + | |

| - | |-

| + | |

| - | |FPP Mode ||001|| FPGA boot from Micro SD Card

| + | |

| - | |-

| + | |

| - | |}

| + | |

| | | | |

| | | | |

| | | | |

| - | [[File:De10-advanced revc msel asmode.jpg|500px]]

| |

| | | | |

| - | :::'''Figure 3-1 The AS mode setting of SW5''' | + | <span style="color:#000080;">'''Getting Help'''</span> |

| | | | |

| - | [[File:De10-advanced revc msel fppmode.jpg|500px]]

| + | Contact us via the following methods for further technical assistance:* |

| | + | ** Terasic Inc.9F, No.176, Sec.2, Gongdao 5th Rd, East Dist, Hsinchu City, Taiwan 300-70Email : [mailto:support@terasic.com support@terasic.com]Web : [http://www.terasic.com/ www.terasic.com] |

| | | | |

| - | :::'''Figure 3-2 The FPP mode setting of SW5'''

| |

| | | | |

| - | ==3.2 Board Setting Headers==

| |

| - | *'''JTAG Interface Header'''

| |

| | | | |

| - | J17 is the header used to set the JTAG bus of FMC connector connect to JTAG interface of DE10-Advanced system.The FMC connector will not be included in the JTAG chain if the headers are set to open(See Figure 3-3). Table 3-2 list the setting of the J17 header.<br/>

| |

| | | | |

| | | | |

| | + | Revision History |

| | | | |

| - | ::::::::'''Table 3-2 JTAG Interface Headers Setting'''

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Header !!Setting !!Descriptions

| |

| - | |-

| |

| - | |J17 ||Open (Default Setting)||Disable the JTAG interface of the FMC connector into the JTAG chain

| |

| - | |}

| |

| | | | |

| - | | + | {| align="center" style="border-spacing:0;width:13.781cm;" |

| - | | + | |

| - | [[File:De10-advanced revc fmc jtag.jpg|500px]]

| + | |

| - | :::::::'''Figure 3-3 The FMC Jtag Header'''

| + | |

| - | | + | |

| - | | + | |

| - | *'''FMC_VCCIO Select Header'''

| + | |

| - | | + | |

| - | JP2 is used to set the VCCIO voltage of FPGA I/O on FMC connector, as1.2V/1.5V/1.8V are supported, the FMC connector can support various I/0 standard FMC daughtercards. Table 3-3 list the FMC_VCCIO Headers Setting.

| + | |

| - | | + | |

| - | ::'''Table 3-3 FMC_VCCIO Headers Setting'''

| + | |

| - | :{| class="wikitable"

| + | |

| - | |-

| + | |

| - | !JP2 Setting !!FMC VCCIO Voltage

| + | |

| | |- | | |- |

| - | |[[File:De10-advanced revc fmc viccio 12.jpg|100px]]||1.2V | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | '''Date''' |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | '''Version''' |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | '''Changes''' |

| | |- | | |- |

| - | |[[File:De10-advanced revc fmc viccio 15.jpg|100px]]||1.5V | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | '''2018.03.16''' |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | '''First publication''' |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| | |- | | |- |

| - | |[[File:De10-advanced revc fmc viccio 18.jpg|100px]]||1.8V(Default Setting) | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| - | |}

| + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| - | | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| - | [[File:De10-advanced revc fmc vccio header.jpg|500px]]

| + | |

| - | | + | |

| - | :::::::'''Figure 3-4 The FMC VCCIO select header''' | + | |

| - | | + | |

| - | | + | |

| - | *'''PMODE Select Header'''

| + | |

| - | | + | |

| - | The USB 3.0 Controller (Cypress FX3) on the DE10-Advanced can be booted from a different sources, selected by the configuration of the PMODE header(JP4/JP5/JP6) on DE10-Advanced. Table 3-4 shows the boot options and associated settings. The default boot device is the from an serial flash via SPI interface.

| + | |

| - | | + | |

| - | | + | |

| - | ::::'''Table 3-4 PMODE Headers Setting''' | + | |

| - | :{| class="wikitable"

| + | |

| - | |-

| + | |

| - | !PMODE[2:0](JP6/JP5/JP4) Setting !!Boot Source

| + | |

| | |- | | |- |

| - | |F00||Sync ADMux (16-bit) | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| | |- | | |- |

| - | |F01||Async ADMux (16-bit) | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| | |- | | |- |

| - | |F11||USB boot | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| | |- | | |- |

| - | |F0F||Async SRAM (16-bit) | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| | |- | | |- |

| - | |F1F||I2C, On Failure, USB Boot is Enabled | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| | |- | | |- |

| - | |1FF||I2C only | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| | |- | | |- |

| - | |0F1(Defualt)||SPI, On Failure, USB Boot is Enabled | + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;color:#ff0000;" | |

| - | |}

| + | | style="border-top:0.5pt solid #999999;border-bottom:0.5pt solid #999999;border-left:0.5pt solid #999999;border-right:none;padding:0cm;" | |

| - | | + | | style="border:0.5pt solid #999999;padding:0cm;" | |

| - | :*'''F''' indicates Floating | + | |

| - | | + | |

| - | | + | |

| - | | + | |

| - | [[File:De10-advanced revc pmode.jpg|500px]]

| + | |

| - | | + | |

| - | :::::::'''Figure 3-5 The PMODE select header''' | + | |

| - | | + | |

| - | ==3.3 Status LED== | + | |

| - | This section describes the all status LED for the interfaces on DE10-Advanced board. Figure 3-6 shows all the status LED on the DE10-advanced. Following are the detailed descriptions of these interface LED.

| + | |

| - | | + | |

| - | [[File:De10 advanced revc ledinterface.jpg|550px]]

| + | |

| - | | + | |

| - | ::: '''Figure 3-6 The status LED on the DE10-Advanced board

| + | |

| - | '''

| + | |

| - | | + | |

| - | *'''UART Interface'''

| + | |

| - | | + | |

| - | :Table 3-5 list the two status LEDs for UART interface.<br/> | + | |

| - | | + | |

| - | ::'''Table 3-5 Status LED for UART Interface''' | + | |

| - | :{| class="wikitable"

| + | |

| - | |-

| + | |

| - | !Component !!Reference !!Status !!Descriptions

| + | |

| - | |-

| + | |

| - | |TXD1 ||UART_TXD||ON||Transmitting

| + | |

| | |- | | |- |

| - | |RXD1 ||UART_RXD||ON||Receiving

| |

| | |} | | |} |

| | | | |

| | | | |

| - | *'''SFP Interface'''

| |

| | | | |

| - | :Table 3-6 list the four status LEDs for SFP interface.<br/>

| |

| | | | |

| - | :::'''Table 3-6 Indicator LED for SFP Interface'''

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Component !!Reference !!Status !!Descriptions

| |

| - | |-

| |

| - | |D4 ||SFPA_MOD0_PRSNT_n||ON||Indicate that the SFP module is present on the SFPA

| |

| - | |-

| |

| - | |D3 ||SFPB_MOD0_PRSNT_n||ON||Indicate that the SFP module is present on the SFPB

| |

| - | |-

| |

| - | |D2 ||SFPC_MOD0_PRSNT_n||ON||Indicate that the SFP module is present on the SFPC

| |

| - | |-

| |

| - | |D1 ||SFPD_MOD0_PRSNT_n||ON||Indicate that the SFP module is present on the SFPD

| |

| - | |}

| |

| | | | |

| | | | |

| - | *'''Ethernet Interface'''

| |

| | | | |

| - | :Table 3-7 list the four status LEDs for Ethernet interface.<br/>

| |

| - |

| |

| - | ::::'''Table 3-7 Status LED for Ethernet Interface'''

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Component !!Reference !!Status !!Descriptions

| |

| - | |-

| |

| - | |D8 ||ETH_LED_TX||ON||Transmitting

| |

| - | |-

| |

| - | |D9 ||ETH_LED_RX||ON||Receiving

| |

| - | |-

| |

| - | |D10 ||ETH_LINK1000||ON||1000Mbps Link UP

| |

| - | |-

| |

| - | |D11 ||ETH_LINK100||ON||100Mbps Link UP

| |

| - | |}

| |

| - |

| |

| - |

| |

| - | *'''Power'''

| |

| - |

| |

| - | :Table 3-8 list the two status LEDs for power.<br/>

| |

| - |

| |

| - | ::::'''Table 3-8 Status LED for Power'''

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Component !!Reference !!Status !!Descriptions

| |

| - | |-

| |

| - | |D31 ||12V~20V Power Indicator||ON||Illuminates when 12V~20V power Power Supply is active

| |

| - | |}

| |

| - |

| |

| - | *'''USB Blaster'''

| |

| - |

| |

| - | :Table 3-6 list the two status LEDs for USB Blaster interface.<br/>

| |

| - |

| |

| - | ::::'''Table 3-5 Status LED for USB Blaster Interface'''

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Component !!Reference !!Status !!Descriptions

| |

| - | |-

| |

| - | |D5 ||JTAG_TX||ON||Illuminates when JTAG interface is transmitting data

| |

| - | |-

| |

| - | |D6 ||JTAG_RX||ON||Illuminates when JTAG interface is receiving data

| |

| - | |}

| |

| - |

| |

| - | ==3.4 JTAG Interface==

| |

| - | Figure 3-2 shows the JTAG interface of DE10-Advanced.Users can access to the JTAG interface through the USB Blaster II circuit or connect external blaster to external blaster header.All the devices which implement JTAG are connect to MAX II device,and switch via MAX II internal switch logic.By using headers J17,users can include FMC connector JTAG interface in the DE10-Advanced JTAG Chain,or exclude them from the JTAG Chain.The default JTAG path for de10-advanced is: USB Blaster II ==> HPS ==> FPGA ==> (Bypass FMC connector) ==> USB Blaster II.When the External JTAG connector is connected to the external blaster, the On board's USB blaster II function will be replaced by the external blaster.<br/>

| |

| - |

| |

| - |

| |

| - | [[File:De10 advanced revc jtagchain.jpg|500px]]

| |

| - | ::::::'''Figure 3-2 JTAG interface of DE10-Advanced'''

| |

| - |

| |

| - | =Chapter 4 FPGA Fabric component=

| |

| - | ==<span style="color:#0000ff;">4.1 USB Type C Port</span>==

| |

| - | The DE10-Advanced board features one USB Type C connector. It is designed for high-speed data transmission with computers and image output applications. Figure 4-1 shows the block diagram of the connection between USB Type C port and FPGA. <br/>

| |

| - | ::::[[File:USB Type C connection.jpg|700px]]

| |

| - | :::::::Figure 4-1 Block diagram of the connection between USB Type C port and FPGA

| |

| - | As shown in Figure 4-1, it connects to FPGA through several switch circuits and USB controllers, users can switch USB Type C connector to a variety of applications as below:

| |

| - | :*USB 3.0 Device to USB Host PC

| |

| - | :*USB 2.0 OTG

| |

| - | :*DisplayPort Source Application (Need DP Source IP)

| |

| - | :*USB 3.1 Gen1 Application (Need USB 3.1 Gen1 IP)

| |

| - | We will describe the circuits diagram and these functions in detail below.

| |

| - |

| |

| - | ===4.1.1 Display Port===

| |

| - | As shown in Figure 3-2,USB type C port can connect to FPGA transceiver. Users can implement a Display port source mode IP in FPGA, the DE10-Advanced board will implement the features of display port source. <br/>

| |

| - | Through the USB Type C cable, users can connect DE10-Advanced board to the monitor which supports Display port interface. Then the image processed by FPGA can be displayed on the monitor. <br/>

| |

| - | Th display port provides data rate up to 5.4Gbps per lane and 4 lanes in total, it supports DisplayPort 1.2a Spec. <br/>

| |

| - | ::::[[File:DisplayPort Source.jpg|600px]]

| |

| - | :::::::::Figure 4-2 USB Type-C Application : DisplayPort TX Source

| |

| - |

| |

| - | :::::::::::::::::Table 4-1 DisplayPort Signal Names and Functions

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name !!FPGA Pin Number !!Description !!I/O Standard

| |

| - | |-

| |

| - | |DP_REFCLK_p || AM31 || Display reference clock form PLL || LVDS

| |

| - | |-

| |

| - | |DP_TX_p[0] || AW37 || TX Lane 1 ||HSSI Differential I/O

| |

| - | |-

| |

| - | |DP_TX_p[1] || AV39 || TX Lane 2 ||HSSI Differential I/O

| |

| - | |-

| |

| - | |DP_TX_p[2] || AU37 || TX Lane 3 ||HSSI Differential I/O

| |

| - | |-

| |

| - | |DP_TX_p[3] || AT39 || TX Lane 4 ||HSSI Differential I/O

| |

| - | |-

| |

| - | |DP_AUX_p || AM22 || Display port AUX port ||DIFFERENTIAL 1.8-V SSTL CLASS I

| |

| - | |-

| |

| - | | DP_DX_SEL || AB27 || Display Port channel TX or RX(Reserve) select. <br/> DP_DX_SEL = 0 : USB TypeC in Display TX mode . <br/> DP_DX_SEL = 1(Reserve) : USB TypeC in Display RX mode ||1.8 V

| |

| - | |-

| |

| - | | DP_AUX_SEL || AC28 || AUX/DDC Selection Control Pin in Conjunction with Dx_SEL Pin ||1.8 V

| |

| - | |}

| |

| - |

| |

| - | ===4.1.2 USB 3.0 Device===

| |

| - | The DE10-Advanced board has one Cypress FX3 USB Controller(CYUSB3014).The USB controller is connected to FPGA through the programmable GPIF II interface, and connect to the external USB Type C connector, It provides USB 3.0 Device application for DE10-Advanced board. <br/>

| |

| - | As shown in Figure 4-3, users can connect FX3 USB Controller to PC through USB Type C cable, and transfer USB 3.0 data between FPGA and USB Host PC with transfer rate 320MByte/s (Using the demonstration provided by Cypress).

| |

| - | ::::[[File:FX3 USB 3.0 Controller application.jpg|600px]]

| |

| - | :::::::::Figure 4-3 FX3 USB 3.0 Controller application

| |

| - |

| |

| - | ===4.1.3 USB 2.0 OTG===

| |

| - | The Cypress FX3 USB controller also has a USB 2.0 OTG controller. It allows the DE10-Advanced board function as an OTG Host to MSC as well as HID-class devices, as shown in Figure 4-4.

| |

| - | ::::[[File:USB 2.0 OTG.jpg|500px]]

| |

| - | :::::::Figure 4-4 USB 2.0 OTG Controller application

| |

| - |

| |

| - | :::Table 4-2 FX3 USB 3.0 Controller Signal Names and Functions

| |

| - | {| class="wikitable"

| |

| - | !Signal Name !!FPGA Pin Number !!Description !!I/O Standard

| |

| - | |-

| |

| - | ||USBFX3_DQ[0]

| |

| - | ||AU21

| |

| - | ||GPIF II Data Bus 0

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[1]

| |

| - | ||AW23

| |

| - | ||GPIF II Data Bus 1

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[2]

| |

| - | ||AW24

| |

| - | ||GPIF II Data Bus 2

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[3]

| |

| - | ||AW25

| |

| - | ||GPIF II Data Bus 3

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[4]

| |

| - | ||AW26

| |

| - | ||GPIF II Data Bus 4

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[5]

| |

| - | ||AV24

| |

| - | ||GPIF II Data Bus 5

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[6]

| |

| - | ||AW28

| |

| - | ||GPIF II Data Bus 6

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[7]

| |

| - | ||AW30

| |

| - | ||GPIF II Data Bus 7

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[8]

| |

| - | ||AW29

| |

| - | ||GPIF II Data Bus 8

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[9]

| |

| - | ||AV27

| |

| - | ||GPIF II Data Bus 9

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[10]

| |

| - | ||AV28

| |

| - | ||GPIF II Data Bus 10

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[11]

| |

| - | ||AU26

| |

| - | ||GPIF II Data Bus 11

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[12]

| |

| - | ||AV23

| |

| - | ||GPIF II Data Bus 12

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[13]

| |

| - | ||AU25

| |

| - | ||GPIF II Data Bus 13

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[14]

| |

| - | ||AR25

| |

| - | ||GPIF II Data Bus 14

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[15]

| |

| - | ||AP24

| |

| - | ||GPIF II Data Bus 15

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[16]

| |

| - | ||AL23

| |

| - | ||GPIF II Data Bus 16

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[17]

| |

| - | ||AM24

| |

| - | ||GPIF II Data Bus 17

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[18]

| |

| - | ||AK25

| |

| - | ||GPIF II Data Bus 18

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[19]

| |

| - | ||AM25

| |

| - | ||GPIF II Data Bus 19

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[20]

| |

| - | ||AT24

| |

| - | ||GPIF II Data Bus 20

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[21]

| |

| - | ||AR26

| |

| - | ||GPIF II Data Bus 21

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[22]

| |

| - | ||AP26

| |

| - | ||GPIF II Data Bus 22

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[23]

| |

| - | ||AP25

| |

| - | ||GPIF II Data Bus 23

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[24]

| |

| - | ||AN24

| |

| - | ||GPIF II Data Bus 24

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[25]

| |

| - | ||AN26

| |

| - | ||GPIF II Data Bus 25

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[26]

| |

| - | ||AK23

| |

| - | ||GPIF II Data Bus 26

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[27]

| |

| - | ||AJ25

| |

| - | ||GPIF II Data Bus 27

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[28]

| |

| - | ||AJ23

| |

| - | ||GPIF II Data Bus 28

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[29]

| |

| - | ||AH23

| |

| - | ||GPIF II Data Bus 29

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[30]

| |

| - | ||AR20

| |

| - | ||GPIF II Data Bus 30

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_DQ[31]

| |

| - | ||AP20

| |

| - | ||GPIF II Data Bus 31

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL0_SLCS_n

| |

| - | ||AV26

| |

| - | ||GPIF II Control Bus 0

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL1_SLWR_n

| |

| - | ||AT22

| |

| - | ||GPIF II Control Bus 1

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL2_SLOE_n

| |

| - | ||AT25

| |

| - | ||GPIF II Control Bus 2

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL3_SLRD_n

| |

| - | ||AR27

| |

| - | ||GPIF II Control Bus 3

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL4_FLAGA

| |

| - | ||AN22

| |

| - | ||GPIF II Control Bus 4

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL5_FLAGB

| |

| - | ||AN23

| |

| - | ||GPIF II Control Bus 5

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL6

| |

| - | ||AL24

| |

| - | ||GPIF II Control Bus 6

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL7_PKTEND_n

| |

| - | ||AL25

| |

| - | ||GPIF II Control Bus 7

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL8

| |

| - | ||AV21

| |

| - | ||GPIF II Control Bus 8

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL9

| |

| - | ||AV22

| |

| - | ||GPIF II Control Bus 9

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL10

| |

| - | ||AU24

| |

| - | ||GPIF II Control Bus 10

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL11_A1

| |

| - | ||AU22

| |

| - | ||GPIF II Control Bus 11

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL12_A0

| |

| - | ||AT23

| |

| - | ||GPIF II Control Bus 12

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_CTL15_INT_n

| |

| - | ||AW21

| |

| - | ||GPIF II Control Bus 15

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_RESET_n

| |

| - | ||AJ24

| |

| - | ||FX3 reset

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_PCLK

| |

| - | ||AT27

| |

| - | ||FX3 clok

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_UART_TX

| |

| - | ||AP23

| |

| - | ||USB to UART transmitter

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_UART_RX

| |

| - | ||AU27

| |

| - | ||USB to UART receiver

| |

| - | ||1.8 V

| |

| - | |-

| |

| - | ||USBFX3_OTG_ID

| |

| - | ||AG26

| |

| - | ||OTG ID pin

| |

| - | ||1.8 V

| |

| - | |}

| |

| - |

| |

| - | ===4.1.4 USB 3.1 Gen1 Application===

| |

| - | As shown in Figure 4-5, user can implement an independent or a third-party USB 3.1 Host or Device IP in FPGA. Through the circuit of FPGA and USB type C connector, the FPGA transceiver can connect to USB Type C connector and achieve the USB 3.o or USB 3.1 Host or Device application.

| |

| - | ::::[[File:Using USB 3.1 Gen 1 IP.jpg|500px]]

| |

| - | :::::::::Figure 4-5 Using USB 3.1 Gen 1 IP

| |

| - |

| |

| - | ::::Table 4-3 USB 3.1 Gen 1 application Signal Names and Functions

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name !!FPGA Pin Number !!Description !!I/O Standard

| |

| - | |-

| |

| - | ||USB_REFCLK_p

| |

| - | ||AB31

| |

| - | ||USB usb reference clock

| |

| - | ||LVDS

| |

| - | |-

| |

| - | ||USB_TX_p

| |

| - | ||AB39

| |

| - | ||USB 3.1 Interface transmitter line

| |

| - | ||HSSI Differential I/O

| |

| - | |-

| |

| - | ||USB_RX_p

| |

| - | ||AA37

| |

| - | ||USB 3.1 Interface receiver line

| |

| - | ||HSSI Differential I/O

| |

| - | |}

| |

| - |

| |

| - | ===4.1.5 Power Application===

| |

| - | The DE10-Advanced board also can be powered through USB Type C port with USB Type C power adpater. The adapter with power above 80W is recommended for DE10-Advanced board. <br/>

| |

| - | Note: Make sure the USB to UART connector (J27) is not connected before using the power adapter, or the DE10-Advanced board can't be power on normally. User can use J27 after the board is powered on.

| |

| - |

| |

| - | ==<span style="color:#0000ff;">4.2 Display Port</span>==

| |

| - | ==4.3 SFP+ Connector==

| |

| - | The development board has four independent 10G SFP+ connectors that use one transceiver channel each from the Arria 10 SoC FPGA device. These modules take in serial data from the Arria 10 SoC FPGA device and transform them to optical signals. The board includes cage assemblies for the SFP+ connectors.Figure 4-3 shows the connections between the SFP+ and Arria 10 SoC FPGA.<br/>

| |

| - | :::::[[File:De10-ad SFP.jpg|600px]]

| |

| - | ::::::::Figure 4-3 Connection between the SFP+ and Arria 10 SoC FPGA<br/><br/>

| |

| - | Table 4-3, Table 4-4, Table 4-5 and Table 4-6 list the four QSF+ connectors assignments and signal names relative to the Arria 10 SoC FPGA<br/>

| |

| - | ::::::Table 4-3 SFP+ A Pin Assignments, Signal Names and Functions

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name !!FPGA Pin Number !!Description !!I/O Standard

| |

| - | |-

| |

| - | |SFPA_TXDISABLE ||PIN_AR28||Turns off and disables the transmitter output ||1.2V

| |

| - | |-

| |

| - | |SFPA_TXFAULT ||PIN_AP28 ||Transmitter fault ||1.2V

| |

| - | |-

| |

| - | |SFPA_TX_p ||PIN_AG37||Transmiter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPA_RX_p ||PIN_AD35 ||Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPA_LOS ||PIN_AN6||Signal loss indicator ||1.2V

| |

| - | |-

| |

| - | |SFPA_MOD0_PRSNT_n|| PIN_AU4||Module present ||1.2V

| |

| - | |-

| |

| - | | SFPA_RATESEL0||PIN_AM19 || Rate select 0 ||3.3V

| |

| - | |-

| |

| - | |SFPA_RATESEL1 ||PIN_AN17 || Rate select 1 ||3.3V

| |

| - | |-

| |

| - | |SFPA_TX_n ||PIN_AG36 || Transmitter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | | SFPA_RX_n ||PIN_AD34 || Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |}

| |

| - |

| |

| - | ::::::Table 4-4 SFP+ B Pin Assignments, Signal Names and Functions

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name !!FPGA Pin Number !!Description !!I/O Standard

| |

| - | |-

| |

| - | |SFPB_TXDISABLE ||PIN_AU5||Turns off and disables the transmitter output ||1.2V

| |

| - | |-

| |

| - | |SFPB_TXFAULT ||PIN_AE10||Transmitter fault ||1.2V

| |

| - | |-

| |

| - | |SFPB_TX_p ||PIN_AF39||Transmiter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPB_RX_p ||PIN_AC37||Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPB_LOS ||PIN_AN12||Signal loss indicator ||1.2V

| |

| - | |-

| |

| - | |SFPB_MOD0_PRSNT_n ||PIN_AT5||Module present ||1.2V

| |

| - | |-

| |

| - | |SFPB_RATESEL0 || PIN_AR18 ||Rate select 0 ||3.3V

| |

| - | |-

| |

| - | |SFPB_RATESEL1 || PIN_AP18 || Rate select 1 ||3.3V

| |

| - | |-

| |

| - | |SFPB_TX_n || PIN_AF38 || Transmitter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPB_RX_n || PIN_AC36 || Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |}

| |

| - | ::::::Table 4-5 SFP+ C Pin Assignments, Signal Names and Functions

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name !!FPGA Pin Number !!Description !!I/O Standard

| |

| - | |-

| |

| - | |SFPC_TXDISABLE ||PIN_AP30||Turns off and disables the transmitter output ||1.2V

| |

| - | |-

| |

| - | |SFPC_TXFAULT ||PIN_AP28||Transmitter fault ||1.2V

| |

| - | |-

| |

| - | |SFPC_TX_p ||PIN_AE37||Transmiter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPC_RX_p ||PIN_AC33||Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPC_LOS ||PIN_AN28||Signal loss indicator ||1.2V

| |

| - | |-

| |

| - | |SFPC_MOD0_PRSNT_n ||PIN_B27||Module present ||1.2V

| |

| - | |-

| |

| - | |SFPC_RATESEL0 || PIN_AK18 ||Rate select 0 ||3.3V

| |

| - | |-

| |

| - | |SFPC_RATESEL1 || PIN_AR17 || Rate select 1 ||3.3V

| |

| - | |-

| |

| - | |SFPC_TX_n || PIN_AE36 || Transmitter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPC_RX_n || PIN_AC32 || Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |}

| |

| - | ::::::Table 4-6 SFP+ D Pin Assignments, Signal Names and Functions

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name !!FPGA Pin Number !!Description !!I/O Standard

| |

| - | |-

| |

| - | |SFPD_TXDISABLE ||PIN_AR28||Turns off and disables the transmitter output ||1.2V

| |

| - | |-

| |

| - | |SFPD_TXFAULT ||PIN_AP21||Transmitter fault ||1.2V

| |

| - | |-

| |

| - | |SFPD_TX_p ||PIN_AD39||Transmiter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPD_RX_p ||PIN_AB35||Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPD_LOS ||PIN_D26||Signal loss indicator ||1.2V

| |

| - | |-

| |

| - | |SFPD_MOD0_PRSNT_n ||PIN_AL28||Module present ||1.2V

| |

| - | |-

| |

| - | |SFPD_RATESEL0 || PIN_AH18 ||Rate select 0 ||3.3V

| |

| - | |-

| |

| - | |SFPD_RATESEL1 || PIN_AW19 || Rate select 1 ||3.3V

| |

| - | |-

| |

| - | |SFPD_TX_n || PIN_AD38 || Transmitter data ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SFPD_RX_n || PIN_AB34 || Receiver data ||HSSI DIFFERENTIAL I/O

| |

| - | |}

| |

| - |

| |

| - | ==4.4 SATA==

| |

| - | Four Serial ATA (SATA) ports are available on the FPGA development board which are computer bus standard with a primary function of transferring data between the motherboard and mass storage devices (such as hard drives, optical drives, and solid-state disks). Supporting a storage interface is just one of many different applications an FPGA can be used in storage appliances. The Arria 10 SoC device can bridge different protocols such as bridging simple bus I/Os like PCI Express (PCIe) to SATA or network interfaces such as Gigabit Ethernet (GbE) to SATA. The SATA interface supports SATA 3.0 standard with connection speed of 6 Gbps based on Arria 10 SoC device with integrated transceivers compliant to SATA electrical standards.<br/>

| |

| - | The four Serial ATA (SATA) ports include two available ports for device and two available ports for host capable of implementing SATA solution with a design that consists of both host and target(device side) functions.Figure 4-4 depicts the host and device design examples.<br/>

| |

| - | ::::[[File:SATA.jpg|400px]]<br/>

| |

| - | :::::Figure 4-4 PC and storage device connection to the Arria 10 SoC FPGA<br/>

| |

| - | The transmitter and receiver signals of the SATA ports are connected directly to the Arria 10 SoC transceiver channels to provide SATA IO connectivity to both host and target devices. To verify the functionality of the SATA host/device ports, a connection can be established between the two ports by using a SATA cable as Figure 4-5 depicts the associated signals connected.Table 4-7 lists the SATA pin assignments, signal names and functions.<br/>

| |

| - | :::[[File:SATA1.jpg|500px]]<br/>

| |

| - | ::::::::Figure 4-5 Pin connection between SATA connectors<br/>

| |

| - | :::::Table 4-7 SATA Pin Assignments,Signal Names and Functions<br/>

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name!!FPGA Pin Number!!Description!!I/O Standard

| |

| - | |-

| |

| - | |colspan="4" |Device

| |

| - | |-

| |

| - | |SATA_DEVICE_REFCLK_p || PIN_M31 || SATA Device reference clock ||LVDS

| |

| - | |-

| |

| - | | SATA_DEVICE_REFCLK_n || PIN_M30 || SATA Device reference clock ||LVDS

| |

| - | |-

| |

| - | | SATA_DEVICE_RX_n0 || PIN_D34 ||Differential receive data input after DC blocking capacitor ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | | SATA_DEVICE_RX_n1 ||PIN_B34 ||Differential receive data input after DC blocking capacitor ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | | SATA_DEVICE_TX_n0 || PIN_B38 || Differential transmit data output before DC blocking capacitor ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | | SATA_DEVICE_TX_n1 ||PIN_A36 || Differential transmit data output before DC blocking capacitor ||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_DEVICE_TX_p0||PIN_B39||Differential transmit data output before DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_DEVICE_TX_p1||PIN_A37||Differential transmit data output before DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_DEVICE_RX_p0||PIN_D35||Differential receive data input after DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_DEVICE_RX_p1||PIN_B35||Differential receive data input after DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |colspan="4" |Host

| |

| - | |-

| |

| - | |SATA_HOST_REFCLK_p||PIN_AF31||SATA Host reference clock||LVDS

| |

| - | |-

| |

| - | |SATA_HOST_REFCLK_n||PIN_AF30||SATA Host reference clock||LVDS

| |

| - | |-

| |

| - | |SATA_HOST_TX_p0||PIN_AJ37||Differential transmit data output before DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_HOST_TX_p1||PIN_AH39||Differential transmit data output before DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_HOST_RX_p0||PIN_AE33||Differential receive data input after DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_HOST_RX_p1||PIN_AF35||Differential receive data input after DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_HOST_TX_n0||PIN_AJ36||Differential transmit data output before DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_HOST_TX_n1||PIN_AH38||Differential transmit data output before DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_HOST_RX_n0||PIN_AE32||Differential receive data input after DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |SATA_HOST_RX_n1||PIN_AF34||Differential receive data input after DC blocking capacitor||HSSI DIFFERENTIAL I/O

| |

| - | |}

| |

| - |

| |

| - | ==4.5 PCIe==

| |

| - | The DE10-Advanced development board features one PCIe Express downstream interfaces (x4 lane) which are designed to interface with a PC motherboard x4 slot via PCIe cable and PCIe adapter card. Utilizing built-in transceivers on a Arria 10 SoC device, it is able to provide a fully integrated PCI Express compliant solution for multi-lane (x4) applications. With the PCI Express hard IP block incorporated in the Arria 10 SoC device, it will allow users to implement simple and fast protocols, as well as saving logic resources for logic applications.

| |

| - |

| |

| - | The PCI Express interface supports complete PCI Express Gen1 at 2.5Gbps/lane, Gen2 at 5.0Gbps/lane, and Gen3 at 8.0Gbps/lane protocol stack solution compliant to PCI Express base specification 3.0 that includes PHY-MAC, Data Link, and transaction layer circuitry embedded in PCI Express hard IP blocks.

| |

| - |

| |

| - | To use PCIe interface, two external associated devices will be needed to establish a link with PC. First, a PCIe half-height add-in host card with a PCIe x4 cable connector called PCA (PCIe Cabling Adapter Card and see Figure 4-5, it will be used to plug into the PCIe slot on a mother board.<br/>

| |

| - | ::::[[File:PCA.jpg|200px]]<br/>

| |

| - | ::::Figure 4-5 PCIe Cabling Adaptor(PCA) card<br/>

| |

| - |

| |

| - | Then,a PCIe x4 cable(See Figure 4-6) will be used to connect DE10-Advanced board and PCIe add-in card, the longest length is up to 3 meters.These two associated devices are not included in DE10-Advanced board. To purchase the PCA card as well as the external cable, please refer to Terasic website [http://pca.terasic.com PCIe x4 Cable Adapter]and [http://www.terasic.com.tw/cgi-bin/page/archive.pl?Language=English&CategoryNo=77&No=687 PCIe x4 Gen.2 Cable].Table 4-8 summarizes the PCI Express pin assignments of the signal names relative to the Arria 10 SoC FPGA.PCIe pin connection is showed in Figure 4-7.<br/>

| |

| - | ::::[[File:PCA Cable.jpg|300px]]<br/>

| |

| - | ::::::Figure 4-6 PCIe External Cable<br/>

| |

| - |

| |

| - |

| |

| - |

| |

| - | [[File:PCIe.jpg|500px]]<br/>

| |

| - | :::::Figure 4-7 PCI Express Pin Connection

| |

| - |

| |

| - |

| |

| - | ::::Table 4-8 PCIe Pin Assignments,Signal Names and Functions

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !Signal Name!!FPGA Pin Number!!Description!!I/O Standard

| |

| - | |-

| |

| - | |PCIE_REFCLK_p||PIN_AH31||PCIe reference clock||LVDS

| |

| - | |-

| |

| - | |PCIE_TX_p[0]||PIN_AR37||PCIe Transmitter data p0||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_TX_p[1]||PIN_AP39||PCIe Transmitter data p1||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_TX_p[2]||PIN_AN37||PCIe Transmitter data p2||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_TX_p[3]||PIN_AM39||PCIe Transmitter data p3||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_RX_p[0]||PIN_AL33||PCIe Receiver data p0||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_RX_p[1]||PIN_AM35||PCIe Receiver data p1||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_RX_p[2]||PIN_AJ33||PCIe Receiver data p2||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_RX_p[3]||PIN_AK35||PCIe Receiver data p3||HSSI DIFFERENTIAL I/O

| |

| - | |-

| |

| - | |PCIE_PERST_n||PIN_AW20||PCIe present,active low||1.8 V

| |

| - | |-

| |

| - | |PCIE_WAKE_n||PIN_AL19||PCIe wake||1.8 V

| |

| - | |}

| |

| - |

| |

| - | ==<span style="color:#ff0000;">4.6 DDR4</span>==

| |

| - |

| |

| - |

| |

| - | The board supports 1GB of DDR4 SDRAM comprising of two x32bit DDR4 devices on FPGA side. The DDR4 signals are connected to the vertical I/O banks on the bottom edge of the FPGA. The DDR4 devices shipped with this board are running at 1067 MHz, for a total theoretical bandwidth of over 66Gbps. Figure 4-8 shows the connections between the DDR4 and Arria 10 SoC FPGA. Table 4-9 lists the pin assignments of DDR4 and its description with I/O standard.

| |

| - | <br/>[[File:DDR4 Device connection.jpg|500px]]

| |

| - |

| |

| - | ::Figure 4-8 The connection between DDR4 and Arria 10 SoC FPGA

| |

| - |

| |

| - | ::::Table 4-9 The pin assignments of DDR4 component and its description with I/O standard

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !FPGA Pin Number !! Signal Name !!Description !!I/O Standard

| |

| - | |-

| |

| - | |PIN_AU7 ||DDR4B_REFCLK_p|| DDR4 A port Reference Clock p ||LVDS

| |

| - | |-

| |

| - | |PIN_AJ11 ||DDR4B_A[0]|| Address [0] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AH12 || DDR4B_A[1] ||Address [1] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AP11 ||DDR4B_A[2]|| Address [2] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AN11 ||DDR4B_A[3]|| Address [3] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AM10 ||DDR4B_A[4]|| Address [4] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AM11 ||DDR4B_A[5]|| Address [5] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AP9 || DDR4B_A[6]|| Address [6] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AN9 ||DDR4B_A[7]|| Address [7] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AR10 || DDR4B_A[8]|| Address [8] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AP10 || DDR4B_A[9]|| Address [9] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AM9 ||DDR4B_A[10]|| Address [10] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AL10 ||DDR4B_A[11]|| Address [11] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AV8 ||DDR4B_A[12]|| Address [12] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AT8 ||DDR4B_A[13]|| Address [13] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AT9 ||DDR4B_A[14]|| Address [14]/WE_n ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AR7 ||DDR4B_A[15]|| Address [15]/CAS_n ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AR8 ||DDR4B_A[16]|| Address [16]/RAS_n ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AU6 ||DDR4B_BA[0]|| Bank Select [0] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AP8 ||DDR4B_BA[1]|| Bank Select [1] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AN8 ||DDR4B_BG[0]|| Bank Group Select[0] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AJ14 ||DDR4B_BG[1]|| Bank Group Select[1] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AL13 ||DDR4B_CK|| Clock p0 ||DIFFERENTIAL 1.2-V SSTL

| |

| - | |-

| |

| - | |PIN_AK13 ||DDR4B_CK_n|| Clock n0 ||DIFFERENTIAL 1.2-V SSTL

| |

| - | |-

| |

| - | |PIN_AK10 || DDR4B_CKE|| Clock Enable pin ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AE12 ||DDR4B_DQS[0] ||Data Strobe p[0] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AL7 ||DDR4B_DQS[1]||Data Strobe p[1] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AR6 ||DDR4B_DQS[2]||Data Strobe p[2] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AT2 ||DDR4B_DQS[3]||Data Strobe p[3] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AF13 ||DDR4B_DQS_n[0]|| Data Strobe n[0] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AK8 ||DDR4B_DQS_n[1]||Data Strobe n[1] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AP6 ||DDR4B_DQS_n[2]|| Data Strobe n[2] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AT3 ||DDR4B_DQS_n[3]|| Data Strobe n[3] ||DIFFERENTIAL 1.2-V POD

| |

| - | |-

| |

| - | |PIN_AJ9 || DDR4B_DQ[0] ||Data [0] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AG11 || DDR4B_DQ[1]|| Data [1] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AF9 || DDR4B_DQ[2]|| Data [2] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AG12 || DDR4B_DQ[3]|| Data [3] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AG9 || DDR4B_DQ[4]|| Data [4] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AF12 || DDR4B_DQ[5]|| Data [5] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AJ10 ||DDR4B_DQ[6]|| Data [6] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AG10 ||DDR4B_DQ[7] ||Data [7] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AL9 || DDR4B_DQ[8]|| Data [8] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AH9 || DDR4B_DQ[9] ||Data [9] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AK6 ||DDR4B_DQ[10]|| Data [10] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AK7 ||DDR4B_DQ[11] ||Data [11] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AH8 ||DDR4B_DQ[12]||Data [12] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AH7 ||DDR4B_DQ[13]|| Data [13] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AJ8 ||DDR4B_DQ[14] ||Data [14] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AE11 ||DDR4B_DQ[15] ||Data [15] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AT4 ||DDR4B_DQ[16]|| Data [16] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AM7 ||DDR4B_DQ[17]|| Data [17] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AP5 ||DDR4B_DQ[18] ||Data [18] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AL5 ||DDR4B_DQ[19]|| Data [19] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AM5 ||DDR4B_DQ[20]||Data [20] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AM6 ||DDR4B_DQ[21]|| Data [21] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AM4 ||DDR4B_DQ[22] ||Data [22] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AR5 ||DDR4B_DQ[23]|| Data [23] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AP1 ||DDR4B_DQ[24]|| Data [24] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AR3 ||DDR4B_DQ[25] || Data [25]||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AN3 ||DDR4B_DQ[26]|| Data [26] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AR1 ||DDR4B_DQ[27]|| Data [27] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AU2 ||DDR4B_DQ[28]|| Data [28] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AP4 ||DDR4B_DQ[29]|| Data [29] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AR2 ||DDR4B_DQ[30]|| Data [30] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AU1 ||DDR4B_DQ[31]|| Data [31] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AF10 ||DDR4B_DM[0] || DDR3 Data Mask[0] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AL8 ||DDR4B_DM[1] || DDR3 Data Mask[1] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AN7 ||DDR4B_DM[2] || DDR3 Data Mask[2] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AN4 ||DDR4B_DM[3] || DDR3 Data Mask[3] ||1.2-V POD

| |

| - | |-

| |

| - | |PIN_AJ13 ||DDR4B_CS_n[0] || Chip Select ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AH14 ||DDR4B_RESET_n ||Chip Reset ||1.2 V

| |

| - | |-

| |

| - | |PIN_AL12 ||DDR4A_ODT[0] || On Die Termination ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AM12 || DDR4A_PAR|| Command and Address Parity Input ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AH11 ||DDR4A_ALERT_n|| Register ALERT_n output ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AH13 ||DDR4A_ACT_n|| Activation Command Input ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AW8 ||DDR4A_RZQ|| External reference ball for output drive calibration ||1.2 V

| |

| - | |}

| |

| - |

| |

| - | The development board also supports one bank of DDR4 SDRAM SO-DIMM on FPGA side. It is wired to support a maximum capacity of 8GB with a 72-bit data bus. Using differential DQS signaling for the DDR4 SDRAM interfaces, it is capable of running at up to 1067MHz memory clock for a maximum theoretical bandwidth up to 132Gbps. Figure 4-9 shows the connections between the DDR4 SDRAM SODIMM and Arria 10 SoC FPGA. The pin assignments for DDR4 SDRAM SO-DIMM are listed in Table 4-10.

| |

| - |

| |

| - | ::[[File:DDR4 SO-DIMM Connection.jpg|400px]]

| |

| - | <br/>Figure 4-9 The connection between the DDR4 SDRAM SO-DIMM and Arria 10 SoC FPGA

| |

| - |

| |

| - | ::::Table 4-10 The pin assignments for DDR4 SDRAM SO-DIMM

| |

| - | :{| class="wikitable"

| |

| - | |-

| |

| - | !FPGA Pin Number !! Signal Name !!Description !!I/O Standard

| |

| - | |-

| |

| - | |PIN_AB12 ||DDR4A_REFCLK_p|| DDR4 A port Reference Clock p ||LVDS

| |

| - | |-

| |

| - | |PIN_AC1 ||DDR4A_A[0]|| Address [0] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AB1 || DDR4A_A[1] ||Address [1] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AB4 ||DDR4A_A[2]|| Address [2] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AA5 ||DDR4A_A[3]|| Address [3] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AA3 ||DDR4A_A[4]|| Address [4] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AA4 ||DDR4A_A[5]|| Address [5] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_Y2 || DDR4A_A[6]|| Address [6] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AA2 ||DDR4A_A[7]|| Address [7] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AB5 || DDR4A_A[8]|| Address [8] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AB6 || DDR4A_A[9]|| Address [9] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_W5 ||DDR4A_A[10]|| Address [10] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_Y5 ||DDR4A_A[11]|| Address [11] ||SSTL-12

| |

| - | |-

| |

| - | |PIN_AA9 ||DDR4A_A[12]|| Address [12] ||SSTL-12

| |

| - | |-

| |